On Our Doorstep

There is so much craftsmanship to be admired in the details of Manchester’s amazing architecture. Have you noticed how many Victorian mosaic floors and thresholds we have in the city centre?

Manchester’s neo-gothic Town Hall has been in the news this week and, just like Buckingham Palace, we’re told that it needs ‘future-proofing’ to ensure its structural integrity. It has an abundance of stained glass leaded windows sagging under their own weight; fairy castle sweeping spiral staircases of stone leading you from one opus sectile marble floor to another featuring, of course, the iconic worker bee and cotton flower motifs in marble mosaic.

In 2015, J W Restoration were commissioned to replicate the cotton flower mosaics for a new floor in Library Walk, which runs between the Town Hall extension and Central Library.

Step out into Albert Square and there are more mosaic details within a few short steps of you. Across on the corner of Lloyd Street and South Mill Street, the circular portico at the entrance to what is now Red’s True Barbecue Restaurant has a fine example.

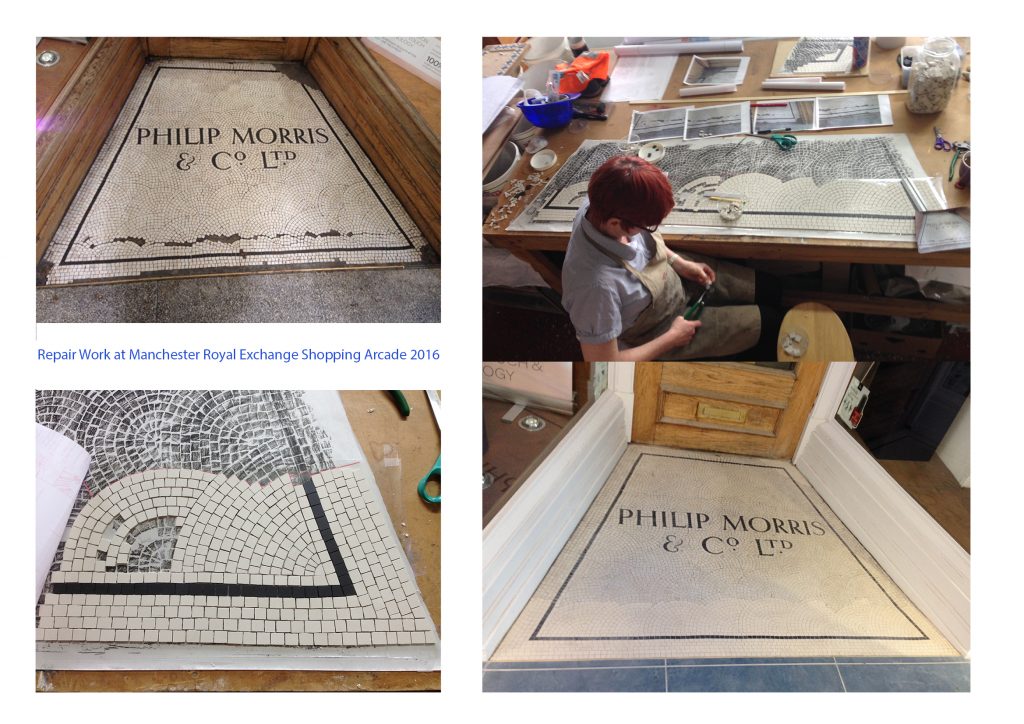

Over at the other side of the square at 14 Princess Street is the Northern Assurance Buildings. Here you can see a large – more than five square metres – threshold mosaic of a similar age, made using the same traditional method and materials. The mosaic material is unglazed porcelain. Just like the floors that I repaired at Victoria Station a couple of years ago and a more recent restoration in the Royal Exchange Shopping Arcade.

Over on Rochdale Road, one of my favourite pubs and former home to the cellar brewery of Marbe Beers, is the Marble Arch pub, well known for its sloping floor. Last Christmas, the Chorlton Mosaic Group was invited to put up an exhibition in the pub’s back room. Below you can see the progress on my “Piece of the Marble”, copied from the pub floor, with a few minor colour modifications. This was purchased by the brewery and now lives on their office wall.

Just like “Well Crafted”, again made in unglazed porcelain, making mosaics like this is great practice for commissioned threshold mosaics like the one below that transformed the entrance to Pettigrew Bakeries in Cardiff.